90 years remanium® - from analog to digital …

a brand makes history

Released: 11.03.2025

Dentaurum's product range has evolved in the long history of the company since it was founded in 1886. Not many dental products have succeeded in staying on the market over decades, not to mention its success in defining existing market conditions. remanium® is, however, a brand that has been continually developed and adapted to the technical advances in dental technology thanks to continuous innovations. In 2025, remanium® will be celebrating its 90th anniversary and one can proudly say that the remanium® alloys are among the best known products in dental prosthetics and can look back on a long history.

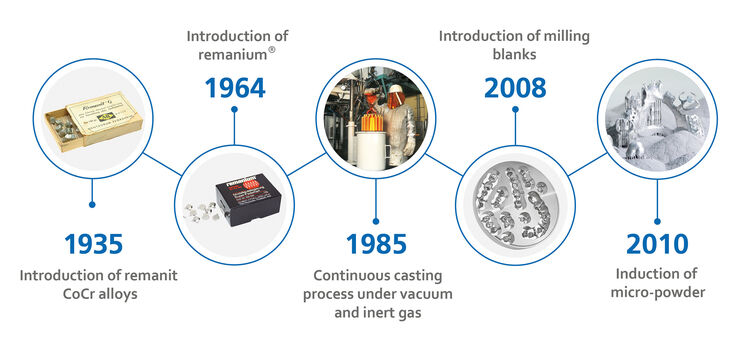

The cobalt-chrome alloy for partial dentures that was presented under the name Remanit in 1935 already displayed fundamental properties and alloy components that can still be found today in the high-quality partial denture alloys under the name of remanium® (since 1964). German dental laboratories have known bonding alloys since 1962. From the end of the 1960s to the beginning of the 1970s, the first bonding alloys with no precious metal content were used.

The cobalt-chrome partial denture alloys were modified further from the beginning of the 1980s so that they could be used as crown, bridge and bonding alloys. The alloy remanium® CD is an example of this modification and has been produced at Dentaurum since 1982 using investment casting methods in the new vacuum melting and casting system. In 1985, the melting unit was extended, enabling continuous casting production under vacuum and inert gas. The new, non-precious CoCr alloys for fixed restorations were of particular interest to the dental world, although they also encountered some fierce opposition.

In the year 2000, the casting alloy remanium® GM 900 was an innovation for dental prosthetics; the titanium- and carbon-free casting alloy was characterized by excellent laser melting properties. In 2003, crown and bridge alloys were produced using the continuous casting process. At this time, the new alloy remanium® star was introduced to the product range, a CoCr alloy with a particularly low degree of hardness. In 2005 came remanium® secura, an extremely reliable and user-friendly CoCr alloy. In the same year remanium® LFC was introduced into the Dentaurum product range, an alloy which had a thermal expansion equivalent to the “biocompatible” alloys based on a high gold content and which could be veneered with the same special ceramic materials.

Dentaurum’s non-precious remanium® casting alloys have been a synonym for quality in prosthetic dentistry for decades and have been used millions of times. To serve new technologies and deliver optimum results with clinically proven alloys, the CoCr casting alloy remanium® star is available today in the same quality for three technologies: alongside the well-known cylinders for dental investment casting, there have been milling blanks for machining since 2008 and the micro-powder for LMF since 2010.

Milling blanks in premium quality have been on offer since 2008. remanium® star MD II has a homogeneous composition with a very high strength and high ductility. These properties are of particular advantage in implantology.

In 2016, the department Digital Technologies came into being to cover the services required for the development and manufacture of products for digital manufacturing. Specialists with the necessary expertise were appointed to serve this fast-growing, progressive domain. The result is a digital support team with comprehensive digital know-how which designs ideal materials for digital dental prosthetics.

Metallic materials, in particular non-precious CoCr alloys, will continue to be a mainstay in the future of prosthetic dentistry. We, at Dentaurum, see proven materials for the production of dental crown and bridge frameworks as the key to high-quality dental restorations and a high level of patient satisfaction. Dentaurum is therefore continuously active in the fields of development, production and quality assurance to preserve the renowned proven quality of the remanium® alloys.

At the IDS, DT François Hartmann will be talking about CoCr and titanium materials and will give an overview of the manufacturing steps. He will also discuss the important material characteristics of remanium® and rematitan®. You can join him at the Dentaurum stand D010/E019 in hall 10.1. Go to https://www.dentaurum.de/lp/eng/ids-2025.aspx if you'd like to learn more.

For more information on the successful remanium® metal alloy family from Dentaurum, go to https://www.dentaurum.de/lp/eng/90-years-remanium.aspx or contact:

DENTAURUM GmbH & Co. KG

Turnstr. 31

75228 Ispringen

Tel. +49 7231 / 803-0

Fax: +49 7231 / 803-295

E-Mail: info@dentaurum.com